Manufacturing with ERP

A manufacturing business has a lot of departments ranging from procurement to production, inventory to sales, and human resources to supply chain. All of them need a single database to keep a check on progress, activities, and updates. Such supervision is led by an ERP system in a profound manner.

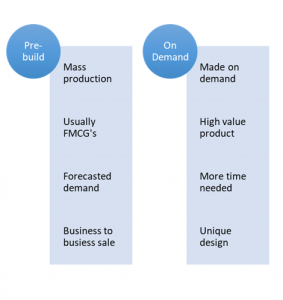

Types of Manufacturing

There exist three types of manufacturing, each of which requires a tremendous amount of resources and skill for execution, and if not supervised properly by an ERP, may result in a significant loss. Customer demands usually vary and depending upon the trends some businesses keep stocks and inventories to meet the needs of customers. On the other hand some businesses wait for the orders to be placed and then schedule their inventory, production, and supply, accordingly.

Common Challenges

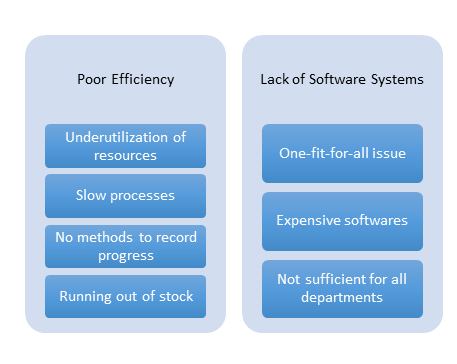

Common Challenges

Every manufacturing business has to tackle and protect itself from the challenges it faces, and progressively learn from them. An ERP system might provide a better insight into how to handle them. It is very obvious to point out a business that is not using an ERP system because of its vague activities and immobilized resources. Such businesses dwell in problems and then they find solutions for them. A few of those problems or challenges are:

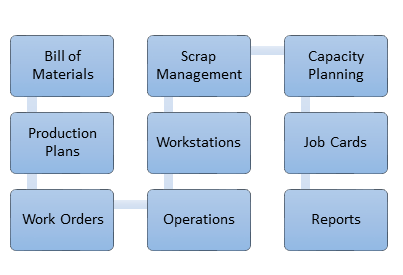

Features of ERP

An ERP system provides key features for the recordings of almost all the accounts, departments, and modules. The system enables the digitization of the business and generating of bills, cards and reports become very smooth. The statistical recording of quotations, invoices, receipts, and statements is obtainable in a knick of time and all departments simultaneously get the progression.

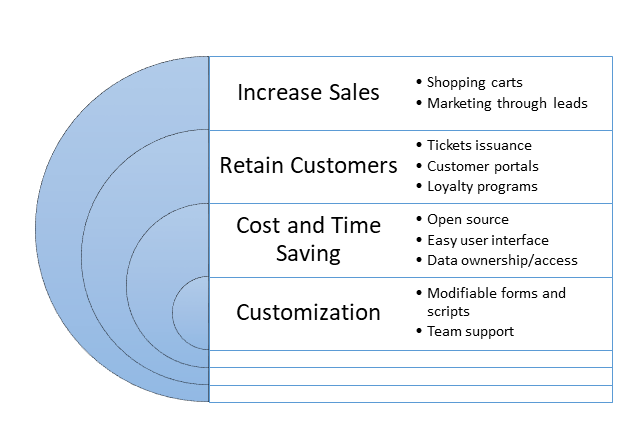

Additional Benefits

Even a manufacturing business has a lot of other aspects to cover and an ERP system can fulfill them with the right use of the application. It holds firm on its advantages that outweigh any of the methods that are done manually. The range of benefits extends to all areas of business due to inter-connectivity.